PTFE 바늘 천공 직물

무엇인가요 PTFE 바늘 구멍을 뚫은 직물?

Baghouse용 PTFE 필터 백을 만들기 위한 여과 매체로서;

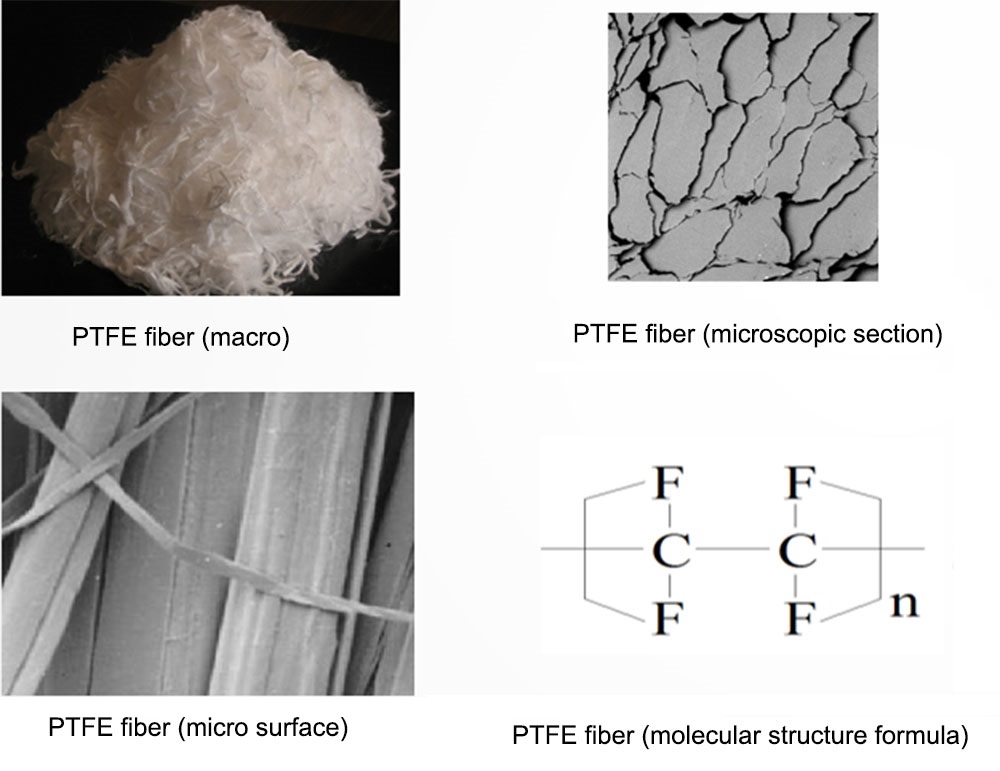

테플론으로도 알려진 PTFE(폴리테트라플루오로에틸렌)는 고온 저항성, 내식성, 내구성 등 탁월한 특성으로 인해 "플라스틱의 왕"으로 간주되어 산업용 여과 응용 분야에 이상적인 소재입니다. Yuanchen에서는 프리미엄급 PTFE(테플론) 섬유를 사용하고 세심한 니들 펀칭 공정을 사용하여 PTFE 니들 펠트 필터 천을 만듭니다. 특수 마감 처리를 거친 이 필터 천은 집진(PTFE 먼지 필터 백) 및 액체 여과(테플론 미크론 등급 필터 백)를 위한 다양한 산업 환경에서 널리 사용됩니다.

PTFE 바늘 구멍을 뚫은 직물의 적용:

PTFE 바늘 천공 직물이 사용되는 일반적인 영역은 다음과 같습니다.

발전:

PTFE 여과 먼지 필터 백은 발전, 특히 석탄 화력 발전소에서 중요한 역할을 합니다. 이는 연도 가스에서 비산회 및 기타 입자상 물질을 제거하여 배출을 줄이고 하류 장비가 손상되지 않도록 보호하는 데 사용됩니다. PTFE의 고온 저항성은 연도 가스가 최대 260°C까지 도달할 수 있기 때문에 이러한 응용 분야에 이상적입니다.

시멘트 생산:

시멘트 생산에서 PTFE 여과 먼지 필터 백은 제조 과정에서 발생하는 먼지 및 입자상 물질을 포착하는 데 사용됩니다. 이러한 먼지 입자는 대기 중으로 방출될 경우 인체 건강과 환경에 해로울 수 있습니다. PTFE 필터 백은 이러한 입자를 효과적으로 제거하여 환경 규정을 준수하고 작업자를 위험한 먼지에 노출되지 않도록 보호합니다.

화학 처리:

화학 처리 공장에서는 부식성 화학물질과 가스를 취급하는 경우가 많습니다. PTFE 여과 먼지 필터 백은 광범위한 화학 물질에 대한 내성이 뛰어나 이러한 용도에 사용하기에 적합합니다. 공정 가스에서 먼지와 입자상 물질을 효과적으로 제거하여 유해 물질이 환경으로 방출되는 것을 방지합니다.

금속 가공:

연삭 및 연마와 같은 금속 가공 작업에서는 다량의 먼지와 입자상 물질이 생성됩니다. PTFE 여과 먼지 필터 백은 이러한 입자를 포착하여 작업장을 오염시키고 작업자의 호흡기 문제를 일으키는 것을 방지하는 데 사용됩니다. PTFE의 낮은 마찰 및 내마모성은 이러한 까다로운 작동 조건에서 필터백의 수명을 연장합니다.

폐기물 소각장:

폐기물 소각장은 폐기물을 고온에서 소각하여 처리하는 데 사용됩니다. PTFE 여과 먼지 필터 백은 소각장 배기 가스에서 입자상 물질을 제거하여 유해한 오염 물질이 환경으로 방출되는 것을 방지하는 데 사용됩니다. 배기 가스가 극도로 높은 온도에 도달할 수 있으므로 PTFE의 고온 저항은 이 응용 분야에 필수적입니다.

아스팔트 공장:

아스팔트 공장은 아스팔트 생산 과정에서 먼지와 입자상 물질을 배출합니다. PTFE 여과 먼지 필터 백은 이러한 입자를 포착하여 배출을 줄이고 주변 환경을 보호하는 데 사용됩니다. PTFE의 달라붙지 않는 특성은 아스팔트가 필터 백에 달라붙는 것을 방지하여 효율적인 여과와 손쉬운 청소를 보장합니다.

채굴 작업:

광산 작업에서는 다량의 먼지와 미립자 물질이 발생하여 작업자와 환경에 건강 위험을 초래할 수 있습니다. PTFE 여과 먼지 필터 백은 광산 환기 공기를 필터링하고 먼지 입자를 제거하며 공기 품질을 개선하는 데 사용됩니다. PTFE의 내구성과 내마모성은 광산 작업의 가혹한 조건에 적합합니다.

간략한 소개 PTFE 바늘 천공 직물:

- 고온 저항, 연속 작동 온도는 최대 260℃, 순간 작동은 최대 280℃까지 가능합니다.

- 대규모 생산이 가능하며, 기존에 비해 가격이 훨씬 저렴해졌습니다.

- 전체 PH 범위에서 사용할 수 있습니다.

- 평소와 같이 긴 서비스 수명은 4년 이상일 수 있습니다.

- 다양한 용도로 모든 제작이 가능합니다.

위안첸의 장점:

1. 거대한 생산 규모:

직원 500명 이상, 생산성: +20000㎡ 필터 천(+4000개 필터 백)/일. Yuanchen 공장에는 PTFE 니들 펀치 직물 생산 전용 작업장이 있습니다.

2. 높은 평판:

상장회사, 17년 이상의 경험, 오직 대기환경 처리에만 집중합니다.

3. 경험이 풍부한 제품 R&D 팀:

다년간의 업계 경험과 특정 작업 조건을 고려하여 고객의 요구에 맞는 제품을 개발하며, 108개의 국내 특허를 취득했습니다.

4. 주요 장비 및 기술:

독일 AUTEFA 풀 라인(세계 최초 자동 바늘 교체 시스템), Bruckner 고온 세팅 라인, 일본 Tokuden 라미네이팅 머신 및 스웨덴 ETON 시스템이 전 공정에 참여하고 있습니다.

5. 우수한 품질을 약속하는 다양한 검사 단계:

+500㎡ 분석 및 테스트 센터, +50 세트 분석 테스트 장비 포함: AFC-133 필터 재료 동적 테스트 플랫폼(독일), PSM-165 필터 기공 크기 테스터(독일), 고성능 액체 크로마토그래피(미국) 등

6. 글로벌 시장에서의 광범위한 경험.

PTFE 섬유 현미경 이미지 및 분자 구조식

PTFE 바늘 천공 직물 기술 사양

|

재료

|

100% PTFE 섬유 |

요소

|

쉘 섬유 |

100% PTFE |

| 튼튼한 면포 |

PTFE |

무게

|

750gsm ± 8% |

두께

|

1.1mm±0.2mm |

통기성 / 200Pa L/d㎡.min

|

70 - 120 |

인장 강도 N/5*20CM

|

경사 |

≥ 650 |

| 씨실 |

≥ 600 |

파단 신율(%)

|

경사 |

≤ 15 |

| 씨실 |

≤ 20 |

온도(℃)

|

계속 온도 |

260℃ |

| 순간온도 |

280℃ |

가공기술

|

열 안정화, 캘린더링, 그슬리기, PTFE 멤브레인 |

애플리케이션

|

시멘트 생산, 철강 플랜트, 건설, 야금, 발전소 등 |

* 필터 백의 구체적인 디자인, 구성 및 크기는 장비 및 여과 요구 사항에 따라 달라질 수 있습니다. 특정 애플리케이션 요구 사항을 충족하기 위해 사용자 정의 옵션을 사용할 수 있습니다.