PTFE Needle Punched Fabric

What is PTFE Needle Punched Fabric?

As a filtration media for making PTFE filter bags for Baghouse use;

PTFE (Polytetrafluoroethylene), also known as Teflon, is considered the "King of Plastics" due to its exceptional properties, including high temperature resistance, corrosion resistance, and durability, making it an ideal material for industrial filtration applications. At Yuanchen, we utilize premium-grade PTFE (Teflon) fibers and employ a meticulous needle punching process to create our PTFE needle felt filter cloths. After undergoing specialized finishing treatments, these filter cloths are widely used in various industrial settings for dust collection (PTFE dust filter bags) and liquid filtration (Teflon micron-rated filter bags).

Application of PTFE Needle Punched Fabric:

Here are some of the common areas where PTFE needle punched fabric are used:

Power generation:

PTFE filtration dust filter bags play a crucial role in power generation, particularly in coal-fired power plants. They are used to remove fly ash and other particulate matter from flue gases, reducing emissions and protecting downstream equipment from damage. The high-temperature resistance of PTFE makes it ideal for this application, as the flue gases can reach temperatures up to 260°C.

Cement production:

In cement production, PTFE filtration dust filter bags are used to capture dust and particulate matter generated during the manufacturing process. These dust particles can be harmful to human health and the environment if released into the atmosphere. PTFE filter bags effectively remove these particles, ensuring compliance with environmental regulations and protecting workers from exposure to hazardous dust.

Chemical processing:

Chemical processing plants often involve the handling of corrosive chemicals and gases. PTFE filtration dust filter bags are highly resistant to a wide range of chemicals, making them suitable for use in these applications. They effectively remove dust and particulate matter from process gases, preventing the release of harmful substances into the environment.

Metalworking:

In metalworking operations, such as grinding and polishing, large amounts of dust and particulate matter are generated. PTFE filtration dust filter bags are used to capture these particles, preventing them from contaminating the workplace and causing respiratory problems for workers. The low friction and abrasion resistance of PTFE extend the lifespan of the filter bags in these demanding operating conditions.

Waste incineration plant:

Waste incineration plants are used to dispose of waste materials by burning them at high temperatures. PTFE filtration dust filter bags are used to remove particulate matter from the incinerator exhaust gases, preventing the release of harmful pollutants into the environment. The high-temperature resistance of PTFE is essential for this application, as the exhaust gases can reach extremely high temperatures.

Asphalt plants:

Asphalt plants emit dust and particulate matter during the production of asphalt. PTFE filtration dust filter bags are used to capture these particles, reducing emissions and protecting the surrounding environment. The non-stick properties of PTFE prevent asphalt from adhering to the filter bags, ensuring efficient filtration and easy cleaning.

Mining operations:

Mining operations generate large amounts of dust and particulate matter, which can pose health risks to workers and the environment. PTFE filtration dust filter bags are used to filter mine ventilation air, removing dust particles and improving air quality. The durability and abrasion resistance of PTFE make it suitable for the harsh conditions found in mining operations.

Brief Introduction Of PTFE Needle Punched Fabric:

- High temperature resistance, continuous operation temperature can up to 260℃, instant operation can up to 280℃.

- Large-scale production available, with the much cheaper price when compared to the before.

- Can be used at full PH range.

- Long service life, as usual can be more than 4 years.

- All of the production rang with various usage are available.

Yuanchen Advantages:

1. Huge production scale:

+500 employees, productivity: +20000㎡ filter cloth (+4000 pcs filter bags) / per day. The Yuanchen factory has a specialized workshop dedicated to producing PTFE needle punched fabric.

2. High reputation:

Listed company, +17 years experiences, Only focus on Air environment treatment.

3. Experienced product R & D team:

We develop products tailored to our customers' needs based on years of industry experience and consideration of their specific working conditions, 108 national patents granted.

4. Leading equipment and technology:

Germany AUTEFA full line (The first automatic needle changing system in the world), Bruckner high temperature setting line, Japan Tokuden laminating machine and Sweden ETON system are participated in the whole process.

5. Multiple inspect steps, dedicated to the commitment of superior quality:

Covers +500㎡ analysis & test center, +50 sets analytical testing equipment: AFC-133 filter material Dynamic test platform (Germany), PSM-165 filter pore size tester (Germany), High performance liquid chromatography (U.S) etc.

6. Extensive experience on global market.

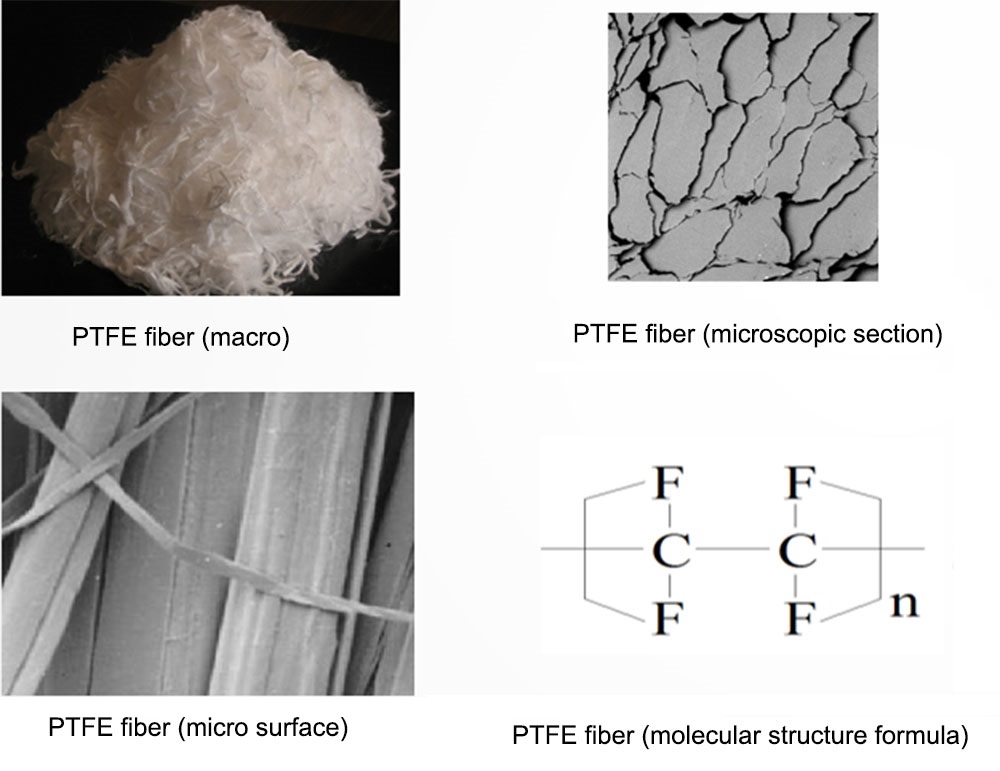

ptfe fiber microscopic image and molecular structure formula

PTFE needle punched fabric Technical Specification

|

Material

|

100% PTFE Fiber |

Component

|

Shell Fiber |

100% PTFE |

| Scrim |

PTFE |

Weight

|

750gsm ± 8% |

Thickness

|

1.1mm ± 0.2mm |

Air Permeability / 200Pa L/d㎡.min

|

70 - 120 |

Tensile Strength N/5*20CM

|

Warp |

≥ 650 |

| Weft |

≥ 600 |

Elongation at break (%)

|

Warp |

≤ 15 |

| Weft |

≤ 20 |

Temperature (℃ )

|

Continue Temperature |

260 ℃ |

| Instant Temperature |

280 ℃ |

Processing Technology

|

Heat Stabilization, Calendering, Singeing, PTFE Membrane |

Application

|

Cement Production, Steel Plant, Construction, Metallurgy, Power Plant, etc. |

* Please note that the specific design, construction, and dimensions of filter bags may vary based on the equipment and filtration requirements. Customization options are available to meet specific application needs.